OLED technology represents a pinnacle of modern visual display innovation. OLED stands for organic light-emitting diode, and it is a type of display that uses organic materials to emit light when electric current is applied.

This technology offers significant benefits over traditional LCD displays, such as higher contrast, lower power consumption, and greater flexibility. As a result, OLED displays are increasingly integral to a range of devices, from smartphones and televisions to laptops and wearable tech.

What is OLED?

OLED is an acronym for organic light-emitting diode. A diode is a device that allows electric current to flow in one direction only. A light-emitting diode (LED) is a type of diode that emits light when electric current passes through it.

An organic light-emitting diode (OLED) is a type of LED that uses organic materials, such as carbon-based molecules or polymers, to emit light. OLEDs are different from conventional LEDs, which use inorganic materials, such as silicon or gallium, to emit light.

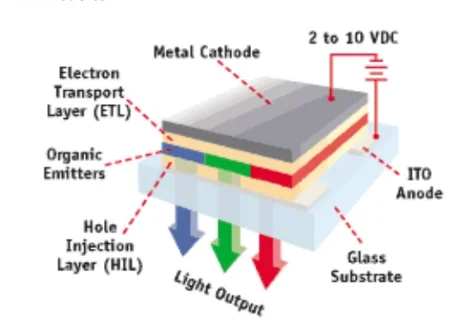

The organic materials used in OLED panels are thin films of organic molecules that create different colors of light when stimulated by electric current. These organic films are sandwiched between two electrodes, an anode and a cathode, which are connected to a power source.

How Does OLED Work?

The basic working process of an OLED is as follows: When an electric current is applied to the OLED, electrons flow from the cathode to the anode, and holes (positive charges) flow from the anode to the cathode.

The electrons and holes are injected into the emissive layer through the electron transport layer and the hole injection layer, respectively. The electrons and holes then move across the emissive layer until they encounter each other and form excitons (bound pairs of electrons and holes).

The excitons release energy in the form of photons (light particles) when they decay back to their original states, process known as electroluminescence. The photons pass through the transparent layers of the OLED and reach the observer’s eye, creating a visible image.

The color and brightness of the light depend on the type and amount of organic molecules used in the film. For example, red, green, and blue OLEDs use different organic materials to produce red, green, and blue light, respectively. By combining these three primary colors, OLED displays can create a full spectrum of colors and images.

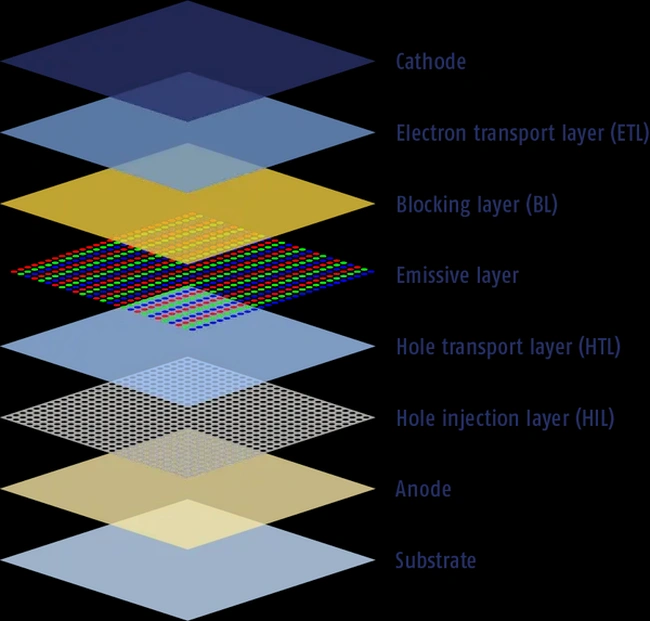

The structure of an OLED panel consists of several layers, each with a specific function. They may vary depending on the particular device but the typical layers are:

- Substrate: Base layer that supports the OLED panel. It can be made of glass, plastic, or metal, depending on the application and flexibility of the display.

- Anode: Positive electrode that injects holes, or positive charges, into the organic layer. It is usually made of a transparent material, such as indium tin oxide (ITO), to allow light to pass through.

- Hole Injection Layer (HIL): This layer is made of organic material that injects holes into the hole transport layer to improve the efficiency of the device.

- Hole Transport Layer (HTL): Transports the holes to the emissive layer, it’s made of organic materials that allow holes to move efficiently.

- Emissive Layer: This layer is where light is made through the recombination of electrons and holes. It’s composed of organic molecules that emit light when an electric current is applied.

- Blocking Layer (BL): Commonly used to improve OLED technology by confining electrons to the emissive layer. It helps ensure that the electrons and holes recombine in the desired region of the emissive layer. Blocking layer helps increase the efficiency of light production.

- Electron Transport Layer (ETL): This layer is made of organic material and transports electrons from the cathode to the emissive layer. It can also block holes.

- Cathode: Negative electrode that injects electrons, or negative charges, into the organic layer. It is usually made of a metallic material, such as aluminum or calcium, to reflect light and enhance the brightness of the display.

Types of OLED Displays

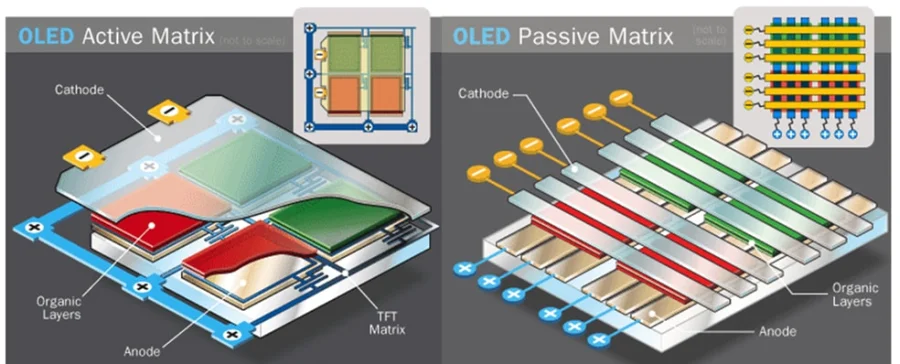

There are two main types of OLED displays, based on how the pixels are controlled and arranged: active-matrix OLED (AMOLED) and passive-matrix OLED (PMOLED).

AMOLED

AMOLED stands for active-matrix organic light-emitting diode. It is a type of OLED display that uses a thin-film transistor (TFT) array to control each pixel individually. A TFT is a switch that can turn on or off the electric current to a pixel.

By using a TFT array, AMOLED displays can achieve higher resolution, faster response time, and lower power consumption than PMOLED displays. AMOLED displays are widely used in smartphones, TVs, laptops, and other high-end devices.

PMOLED

PMOLED stands for passive-matrix organic light-emitting diode. It is a type of OLED display that uses a simple grid of rows and columns to control the pixels. Each row or column is connected to a common electrode, and the pixels are turned on or off by applying electric current to the intersecting points.

PMOLED displays are simpler and cheaper to produce than AMOLED displays, but they have lower resolution, slower response time, and higher power consumption. PMOLED displays are mainly used in small and low-cost devices, such as smartwatches, calculators, and digital clocks.

Fabrication Methods for OLEDs

Organic Light Emitting Diodes are fabricated using two primary methods: dry and wet methods.

Dry Method

The dry method involves the conversion of raw organic materials from a solid powder form into a gas phase. This is typically achieved through a process known as vacuum thermal evaporation (VTE).

In this method, the powder is heated to above its sublimation temperature to form a vapor which then condenses onto a substrate, all while in a high-vacuum environment. VTE produces OLEDs with the best performance in terms of efficiency and lifetime, in addition to being the most mature manufacturing method.

Wet Method

The wet method involves the application of organic materials dissolved in a solution or a condensed liquid phase. In this wet form, the solution is applied to the substrate by spin coating, slit coating, inkjet printing, or other methods and then dried before applying the next layer.

In both methods, the organic material is finally condensed onto a substrate in a solid-phase form.

Other Methods

Other methods such as solution processing hold the promise of lower manufacturing costs due to easier scalability and better material utilization, however none have reached commercial scale yet despite many years of development.

A lot of progress has been made over the years to reduce the performance gap between VTE and non-VTE methods. However, non-VTE approaches typically lag behind in at least one or more performance attributes, such as lifetime.

In addition to deposition techniques of each organic layer, RGB patterning technologies are important. These RGB patterning technologies are vacuum deposition using fine metal masks, wet processes such as ink‐jet, nozzle printing, relief printing and laser patterning process.

Advantages of OLED Technology

OLED technology has many advantages over traditional LCD technology, such as:

Picture quality

OLED displays can produce deeper blacks, higher contrast and more vivid colors than LCD displays. This is because OLED displays do not require a backlight to illuminate the pixels, unlike LCD displays, which use a backlight that can reduce the contrast and color accuracy of the display.

OLEDs can achieve wide color gamut because they can produce pure and saturated colors without using color filters or backlighting. Color gamut is the range of colors that a display can reproduce accurately and faithfully. Wide color gamut can improve the color accuracy and richness of the images and make them more vibrant and realistic.

LCDs inherently face challenges with viewing angles because they rely on blocking light to display images. On the other hand, OLEDs generate their own light, allowing for a wider viewing angles.

OLED displays typically have faster refresh rates than LCD screens. This is because OLEDs are purely electronic, while LCD screens have to physically move tiny crystals embedded in the surface of the screen, which can be relatively slow to respond.

Fast response times reduces motion blur and ghosting effects, therefore OLEDs are often a popular choice for gaming and high-speed action viewing. However, it’s worth noting that both mid- and high-end LCDs and OLEDs typically have a 120Hz refresh rate.

OLED displays can also support high dynamic range (HDR), which enhances the brightness and color range of the images.

Efficiency

OLED displays can consume less power than LCD displays, especially when displaying dark or black images.

This is because OLED displays only use electric current to light up the pixels that are needed, unlike LCD displays, which use a constant backlight that consumes power regardless of the image.

OLED displays can also adjust the brightness and color temperature of the display according to the ambient light, which can save more energy and improve the user’s comfort.

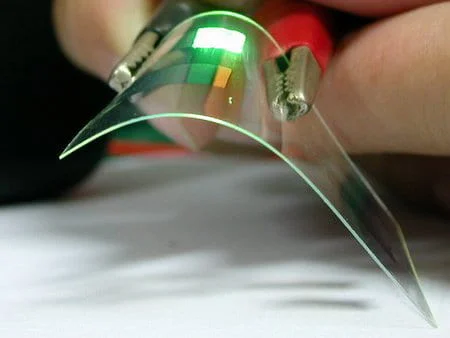

Flexibility

OLED displays can be made thinner, lighter, and more flexible than LCD displays, because they do not require a rigid substrate or a backlight to support the panel.

They can be bent, folded, rolled, or even stretched, without affecting the performance or quality of the display.

OLED displays can also be transparent, which can enable new applications and designs, such as transparent TVs, windows, or glasses.

Challenges in OLED Technology

Despite the many advantages of OLED technology, there are also some challenges and limitations that need to be overcome, such as:

OLED displays are still more expensive to produce than LCD displays, due to the high cost of the organic materials, the complex manufacturing process, and the low yield rate.

They also have a shorter lifespan than LCD displays, due to the degradation of the organic materials over time.

OLED displays are more prone to burn-in, which is a permanent image retention that occurs when a static image is displayed for a long time, such as a channel logos, news tickers, or video game HUDs.

They also have a lower brightness than LCD displays, which can affect the visibility and readability of the display in bright environments.

OLED displays also face competition from other emerging display technologies, such as quantum dot LED (QLED), micro LED (µLED), and mini LED, which can offer similar or better performance and quality than OLED displays, at a lower cost and higher reliability.

OLED vs Other Display Technologies

| Display Technology | Backlight | Contrast Ratio | Color Gamut | Response Time | Lifespan | Burn-in | Manufacturing Cost |

|---|---|---|---|---|---|---|---|

| OLED | No | Infinite | Wide | Fast | Limited | Prone | High |

| LCD | Yes | Low | Narrow | Slow | Long | Rare | Low |

| LED | Yes | Medium | Medium | Medium | Long | Rare | Medium |

| QLED | Yes | High | Wide | Medium | Long | Rare | High |

As you can see, OLED technology outperforms other display technologies in terms of contrast ratio, color gamut, and response time, but it also has some drawbacks in terms of lifespan, burn-in, and manufacturing cost.

Future of OLED Technology

OLED technology is constantly evolving and improving, and it has a bright future in the visual display industry. Some of the possible future applications and developments in OLED technology are:

Foldable devices

OLED technology can enable the creation of flexible and foldable devices, such as smartphones, tablets, laptops, or TVs, that can change their shape and size according to the user’s preference and need.

For example, a foldable smartphone can be unfolded into a tablet, or a flexible TV can be rolled up into a tube. These devices can offer more convenience, portability, and functionality to the users.

Wearable and implantable devices

OLED technology can also enable the creation of wearable and implantable devices, such as smartwatches, glasses, contact lenses, or even e-tattoos, that can display information or images on the user’s body or skin.

These devices can offer more personalization, customization, and integration to the users, as well as new health and wellness applications and services.

Augmented and virtual reality

OLED technology can also enable the creation of augmented and virtual reality devices, such as VR/AR headsets, smart glasses, goggles, or helmets, that can display immersive and realistic images and videos to the user’s eyes. It does so by implementing Micro-OLED technology.

Micro-OLEDs are a type of OLED technology that can create very small and high-resolution displays. They enable more realism and clarity in devices, especially for content that requires high visual quality and performance.

These devices can offer more entertainment, education, and communication to the users, as well as presenting new realities and possibilities.

Blue PHOLED materials

PHOLED displays are displays that utilize phosphorescent OLEDs instead of fluorescent OLEDs. At present, all OLED displays use red and green PHOLED materials for their subpixels. However blue subpixels continue to be made of fluorescent materials.

Conversion rate of electric current into light is 100% for phosphorescent OLED subpixels. In contrast, fluorescent OLED subpixels can only achieve a 25% conversion rate. This not only affects power efficiency but impacts peak brightness as well.

However, this is expected to change near future. Universal Display (UDC), the inventor of PHOLED technology, is in the process of making blue PHOLED subpixel materials accessible to display manufacturers for incorporation into their OLED TVs.

PHOLED may seem like a minor modification to the existing OLED technology but it represents a significant improvement.

Conclusion

OLED technology is one of the most advanced and innovative forms of visual display in the modern world. It is widely used in a variety of applications, from smartphones and televisions to wearable devices and lighting solutions.

Its ability to produce vibrant colors and deep blacks makes it a popular choice for high-end consumer electronics. Furthermore, the flexibility of OLED materials opens up possibilities for curved and foldable displays, pushing the boundaries of design in the tech industry.

However, despite its numerous advantages, OLED technology is also facing some challenges and considerations that need to be overcome. Researchers and manufacturers are continually working on improvements and innovations to overcome these hurdles and further enhance the performance of OLED displays. As technology continues to evolve, OLED is expected to play a significant role in shaping the future of visual display technology.

Q&A

Why is OLED so expensive?

OLED technology is relatively new and complex to manufacture. The production process involves specific, expensive components, including organic materials. A significant percentage of OLED panels produced may end up being unusable, leading to higher production costs. As the technology matures and manufacturing processes improve, the prices of OLED displays are expected to come down.

Who invented OLED technology?

The invention of practical OLED (Organic Light-Emitting Diode) technology is primarily credited to chemists Dr. Ching W. Tang and Steven Van Slyke, who were working together at Eastman Kodak. In 1987, they published a groundbreaking paper describing a novel two-layer OLED structure that achieved significantly higher efficiency and operated at lower voltages than previous attempts.

While the basic phenomenon of electroluminescence in organic materials had been observed earlier by others, Tang and Van Slyke’s work represented the crucial breakthrough that made OLEDs a viable and practical technology, paving the way for their use in modern displays.

Is OLED good or bad for eyes?

OLED displays are generally considered better for your eyes. They emit less blue light, which is known to cause damage to the retina and potentially lead to diseases such as macular degeneration. Furthermore, OLED displays can be easier on the eyes due to their high contrast ratio and true black capabilities.

Is OLED really that much better?

OLED displays are often considered superior to other display technologies. They offer better contrast ratios and true blacks because each pixel in an OLED display is individually lit. If the image requires a part of the screen to be black, those pixels can turn off completely, resulting in a more accurate and vibrant image.

What is the difference between LED and OLED?

The main difference between LED and OLED lies in the way they emit light. LED displays require a backlight to illuminate their pixels, while each pixel on an OLED emits its own light. This allows OLED displays to be thinner and more flexible than LED displays. It also means that OLEDs can display true black by completely turning off pixels.

Which is better, OLED or QLED?

Neither technology is universally “better” as they excel in different areas. OLED TVs offer perfect black levels and infinite contrast because each pixel lights itself, providing stunning picture quality, especially in dark rooms. QLED TVs (which use LED backlights with a quantum dot layer) typically get much brighter and display vibrant colours, making them excellent choices for bright rooms, and they aren’t susceptible to burn-in like OLED can potentially be. Your ideal choice depends on your viewing environment and priorities like contrast versus brightness.

Is OLED better than 4K?

This question compares two different things: OLED is a display panel technology, while 4K (or Ultra HD) is a measure of screen resolution (the number of pixels). They aren’t mutually exclusive. Most modern OLED TVs are 4K resolution. OLED technology determines how the picture looks (e.g., contrast, black levels), while 4K resolution determines the picture’s sharpness and detail. You can have 4K resolution on various panel types (like QLED or standard LED). Therefore, it’s not about one being better, but rather that an OLED panel combined with 4K resolution creates a very high-quality, detailed viewing experience.

Read Next